JEET successfully developed 1.7mm ultra-fine videoscope

Industrial endoscope technology has unique advantages, which can extend people's viewing distance, as well as change the viewing direction. It helps users to accurately inspect the true condition of the inner surface of the container or pipeline, without disassembling the equipment, which cannot be replaced by other inspection instruments. For example, in aviation applications, the industrial videoscope probe can be inserted into the aircraft engine to directly observe the true internal conditions or the internal conditions of equipment parts after operation; effectively inspect the surface conditions of relatively hidden or narrow parts. This inspection method is simple, reliable, intuitive and effective. Whether in the aerospace field, the electronics industry, and other manufacturing and maintenance industries, the application of borescopes in NDT field has achieved good effects, solved many difficult problems, ensured the normal operation of the entire equipment, and avoided accidents.

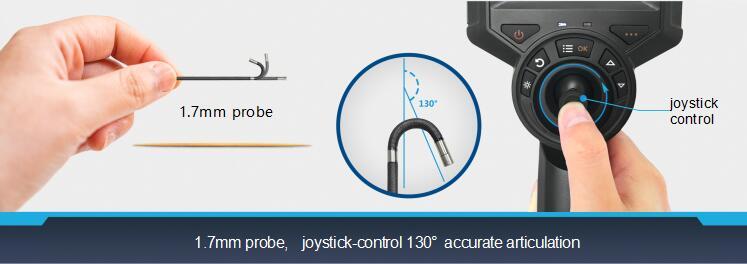

The borescope tube has different diameters. The common tube diameters on the market are 8mm, 6mm, 4.2mm, 3.8mm, 2.4mm, etc. After unremitting efforts, JEET team has successfully developed 1.7mm ultra-fine flexible borescope. It is mainly used in the quality inspection of small pipeline welding, stainless-steel capillary inner surface, elbows and welds of the pharmaceutical fluid pipelines, hydraulic casting, pump body casting, mechanical parts casting, and preliminary quality control of welding and casting defects in pipelines and cavities, surface finish, deep holes, blind holes, staggered holes, sand inclusions, burrs, etc.