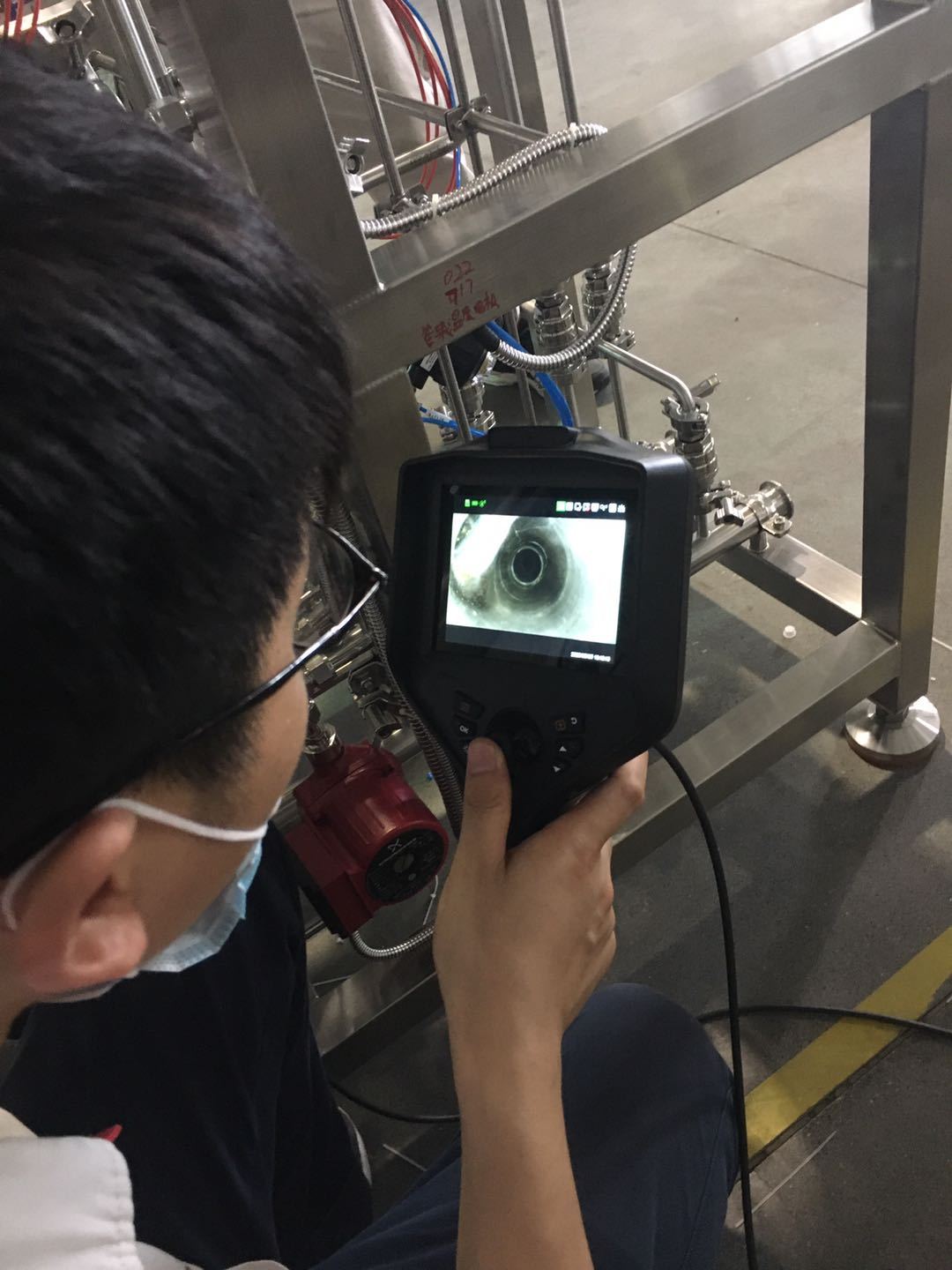

Video borescope application in pharmaceutical industry

The main function of videoscope is to inspect the inside of pipeline and equipment that cannot be recognized by human eyes. It mainly checks whether there are cracks, white spots, sand holes, pores and slag on the surface of pipeline and welding seam.

Any careless welding of pipeline in food and pharmaceutical engineering may lead to serious consequences.The clean pipeline in the equipment is an important part of the pharmaceutical production process and an important carrier for the transmission of various media in the process of food and pharmaceutical production.At present, all sterile clean pipes are made of stainless steel and adopt the most advanced laser welding technology.

GMP, FDA certification and drug production process have very strict requirements on the quality of pipeline weld.For example, injection water pipeline, material pipeline, pure steam pipeline, etc. are required to provide pollution-free, corrosion resistance, inner wall smooth and other good medium transportation environment.It requires manufacturers and construction units to provide qualified products in line with the special requirements of the pharmaceutical industry.

Industrial videoscope, as an important nondestructive testing instrument, provides strong support for the inspection of welding surface in order to ensure the welding quality of pipeline.It can be detected without disassembly and equipment stopping running. It can take pictures and video to check the defective parts, so as to monitor, record, store and analyze the image of the field of view, and make inspection report. So,Jeet videoscope should be your first choice.